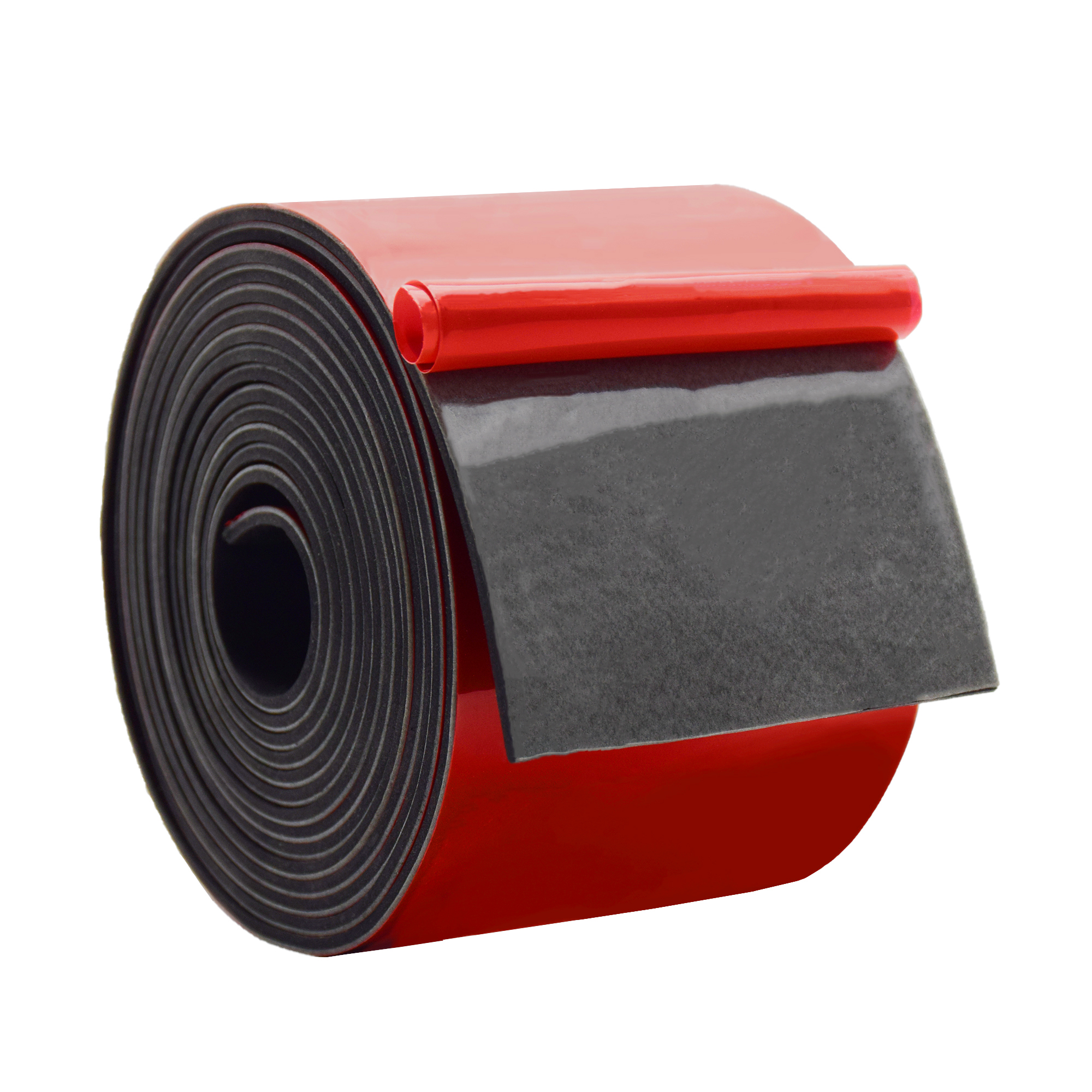

Adhesive Rubber Strips

Adhesive Rubber Strips

Adhesive rubber strips are versatile products used for sealing, cushioning, insulating, and dampening vibrations in various applications. They typically come in rolls or strips with adhesive backing for easy installation.

Product overview

Here's some information about adhesive rubber strips: Material Composition: Adhesive rubber strips are typically made from various types of synthetic rubber compounds, including neoprene, EPDM (Ethylene Propylene Diene Monomer), silicone, or foam rubber. The choice of material depends on the specific application requirements such as temperature resistance, chemical resistance, and flexibility.

Adhesive Backing

Adhesive rubber strips feature a pressure-sensitive adhesive backing on one side, allowing for easy and secure attachment to surfaces. The adhesive backing may be made from acrylic, rubber-based, or silicone-based adhesives, depending on the application and surface compatibility.

Properties

Weather Resistance: Adhesive rubber strips may offer varying degrees of weather resistance depending on the material composition. Silicone rubber, for example, provides excellent resistance to UV rays and weathering.

Temperature Resistance: The temperature resistance of adhesive rubber strips depends on the material used. Neoprene and silicone rubber offer high temperature resistance, while EPDM rubber is suitable for moderate temperature applications.

Compression Set Resistance: Adhesive rubber strips may exhibit good compression set resistance, allowing them to maintain their shape and sealing properties over time.

Flexibility: Rubber strips are typically flexible and conformable, allowing them to adapt to irregular surfaces and contours.

Chemical Resistance: Depending on the specific rubber compound used, adhesive rubber strips may offer resistance to oils, solvents, acids, and other chemicals.

Applications

Sealing: Adhesive rubber strips are commonly used for sealing gaps and joints in windows, doors, cabinets, and automotive applications to prevent air, dust, and moisture infiltration.

Cushioning and Insulation: Rubber strips are used for cushioning and insulating purposes in appliances, electronics, HVAC systems, and machinery to absorb shocks, vibrations, and noise.

Gasketing: Rubber strips are utilized as gaskets in industrial equipment, engines, pumps, and valves to provide a sealing barrier against fluids and gases.

Weather Stripping: Adhesive rubber strips are employed as weather stripping around doors and windows to improve energy efficiency and thermal insulation.

Automotive Applications: Rubber strips are used in automotive applications for vibration damping, weather sealing, and gasketing purposes.

Availability

Adhesive rubber strips are available in various widths, thicknesses, and lengths to suit different application requirements. They can be purchased from hardware stores, industrial suppliers, specialty manufacturers, and online retailers.

Customization

Some suppliers offer customization options for adhesive rubber strips, allowing customers to order products tailored to their specific requirements in terms of size, material, adhesive strength, and other properties.

In summary, adhesive rubber strips are versatile products with a wide range of applications in sealing, cushioning, insulating, and dampening vibrations. They offer flexibility, weather resistance, and ease of installation, making them indispensable in various industries and applications.

Our Featured Products

Neoprene Rubber

Neoprene rubber sheets and strips are popular materials known for their versatility and durability. Neoprene is a type of synthetic rubber that offers excellent resistance to oils, chemicals, UV rays, and weathering, making it suitable for a wide range of applications across various industries.

Learn More